Waste Wood Shredding Line for Heat Production (Sweden)

In response to the shifting paradigm of renewable district energy systems, Azortum has executed a comprehensive design-build initiative at Jämtkraft’s combined heat and power (CHP) facility in Östersund, Sweden.

This multifaceted infrastructure development represents a landmark advancement in the utilization of secondary biomass streams, integrating robust mechanical engineering, precision control systems, and thermodynamic performance optimization to ensure reliable and scalable fuel preparation within a harsh climatic context.

The upgraded facility not only significantly increases the share of recycled wood as an energy input but also establishes a template for sustainable energy system retrofitting in similar geographies.

- Project: Jämtkraft's Combined Heat and Power Facility Waste Wood Shredding Line in Östersund, Sweden

- Objective: Elevation of Recycled Wood Content From 20% to 75% Within The Fuel Mix

- Nominal Throughput: 70 Metric Tons per Hour

- Add-On: 'Winter Mode' For Freezing Temperatures

Project Context and Strategic Imperative

Initiated in the fourth quarter of 2023, the Jämtkraft-Azortum partnership aligns with a broader strategic transition across the Nordic energy sector toward carbon neutrality, circular material flows, and adaptive infrastructure capable of withstanding environmental and regulatory stressors.

The project's core objective is the elevation of recycled wood content from 20% to 75% within the fuel mix—a target requiring a paradigm shift in both material logistics and system engineering.

The implications of this shift are multifaceted, spanning reductions in virgin biomass dependency, decreased landfill waste, enhanced local fuel security, and alignment with EU decarbonization benchmarks.

Systems Engineering and Integrated Design

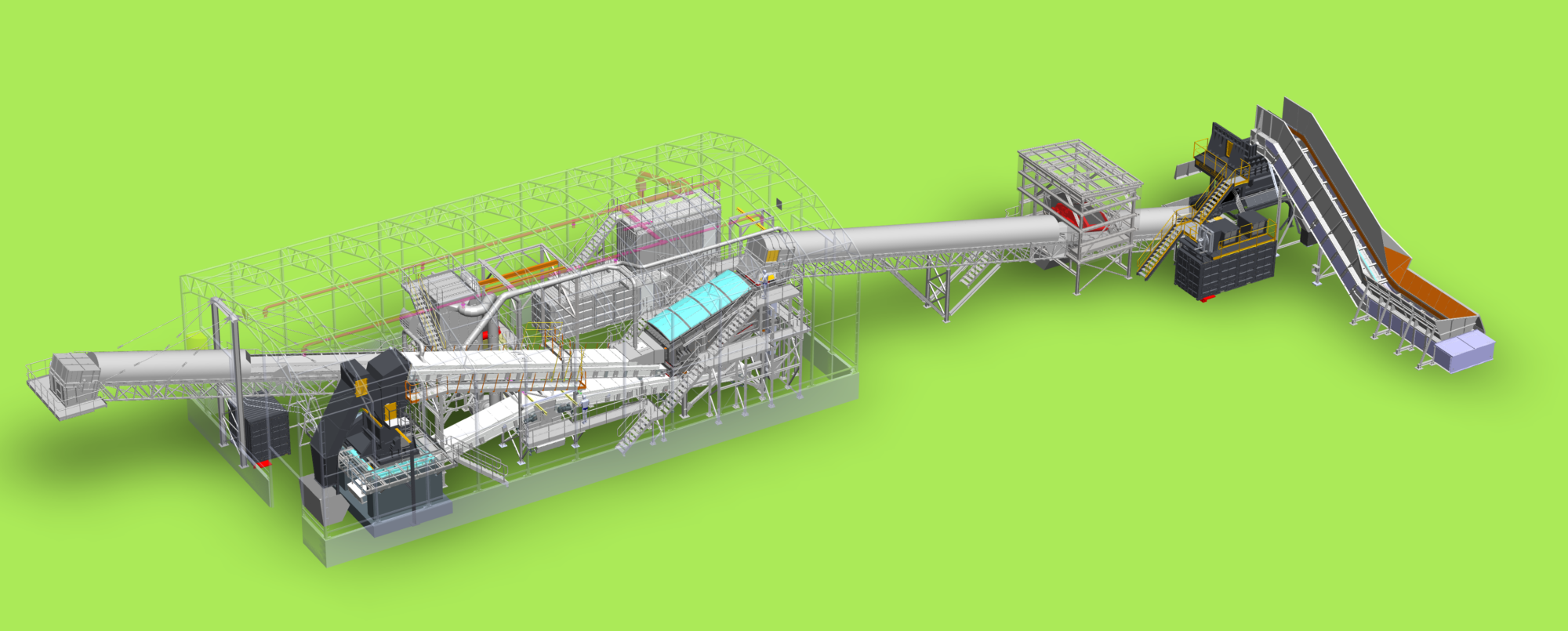

Azortum's methodology entailed a vertically integrated approach to mechanical and systems engineering, resulting in a bespoke solution anchored by a 2.1-meter-wide conveyor infrastructure nested within a 3-meter operational envelope.

This conveyor system facilitates seamless feeding of a high-torque, triple-motorized shredding system, designed to accommodate heterogeneous waste wood input streams at a nominal throughput of 70 metric tons per hour.

This volumetric capacity was calibrated to accommodate both current operational demands and future scalability for increased CHP throughput.

The mechanical line features a sequential shredding architecture—initial maceration followed by precision fractionation—to ensure tight control of particle size distributions suitable for direct combustion.

Operational Continuity Through Intelligent Layout and Modularity

The physical design of the processing line adheres to an uninterrupted linear conveyor schema, thereby eliminating angular transitions that are prone to jamming, especially when processing elongated wood debris or irregular particle geometries.

Modularity was prioritized in every mechanical node, enabling streamlined maintenance, rapid substitution of wear-prone elements, and system reconfiguration as operational requirements evolve.

Central to this is the integration of adjustable screening modules that allow for live calibration of output fractions in response to fuel specification dynamics or downstream boiler parameter fluctuations.

Automation Framework and Subsystem Integration

Beyond the mechanical scope, Azortum delivered a distributed automation architecture embedded with autonomous control protocols and full integration into Jämtkraft’s plant-wide supervisory systems via OPC UA.

The software and instrumentation layer enables real-time diagnostics, anomaly detection, and predictive maintenance across all operational nodes.

Supporting subsystems—including SBF 110-compliant smoke and fire suppression, pressurized air regulation, forced ventilation, water misting for dust abatement, and closed-loop lubrication—were engineered as interoperable modules, streamlining both commissioning and long-term O&M procedures.

Dust, Moisture, and Particulate Mitigation

Given the stochastic nature of waste wood moisture content and bulk density, Azortum applied a comprehensive materials handling strategy.

Sloped chutes with aggressive inclinations and low-adhesion coatings mitigate biomass agglomeration, while a dual-mode dust control system balances passive suppression via high-humidity misting with active evacuation through modular extraction units.

The aim is twofold: reduce occupational and environmental particulate exposure while also preserving the functional longevity of downstream filtration and combustion equipment.

Cold-Climate Engineering and Thermal Integrity

In acknowledgment of the severe subarctic operating conditions in Östersund, the pre-treatment line incorporates a suite of thermal resilience measures.

These include a "winter mode" operation in which conveyor systems cycle at reduced speed during idle periods to prevent freeze-locking.

The entirety of the mechanical envelope is housed within a semi-permanent PVC structure, affording protection from precipitation, ice accumulation, and thermal shock events.

Structural Enclosure and Environmental Hardening

The structural shell surrounding the fuel prep system is fabricated from tensioned PVC membranes mounted on an industrial-grade support frame.

This enclosure mitigates ingress of snow, sleet, and windborne debris, while also reducing thermal gradients that could compromise mechanical tolerances.

Passive airflow management within the enclosure is facilitated through variable intake vents and strategically placed exhaust plenums, balancing condensation control with energy conservation.

Adaptive Capacity, Scalability, and Infrastructure Longevity

Configurability is not a peripheral attribute but a core design philosophy of the Azortum solution. The shredding logic supports multiple operational routines, each of which can be programmed, modified, and optimized by local operators based on fuel type, weather forecasts, or maintenance schedules.

Taken together, these features ensure a high degree of operational elasticity, thereby extending the infrastructure’s lifecycle and bolstering its economic return.

Executional Discipline and Stakeholder Engagement

According to Gert Raag, Azortum’s lead project executive, the complexity of the solution necessitated iterative prototyping and the concurrent development of multiple design streams.

“Our ability to anticipate downstream integration challenges and environmental edge-cases enabled us to deliver a resilient system architecture while remaining within schedule boundaries,” he commented.

Stakeholder alignment and disciplined scope management were pivotal in mitigating the cascading impacts of minor upstream delays.

Sectoral Relevance and Technical Legacy

This project sets a precedent for how advanced engineering solutions can meet the nuanced needs of decentralized renewable heat networks.

By elevating the technical fidelity of fuel preparation—from material intake to combustion readiness—Azortum reinforces the operational and environmental integrity of CHP infrastructure.

The integration of high-availability automation, safety-focused subsystem architecture, and modular adaptability makes the Östersund line a benchmark in waste-derived fuel engineering.

Conclusion: Toward a Replicable Framework for Renewable Thermal Energy Transition

The waste wood pre-treatment facility co-developed by Azortum and Jämtkraft exemplifies the synergetic potential of industrial engineering and climate policy.

It delivers an infrastructure-ready response to pressing energy transition imperatives while maintaining operational pragmatism and cost-efficiency.

As the Nordic-Baltic and Central European regions pursue aggressive decarbonization trajectories, this project provides a replicable blueprint for CHP operators seeking to enhance resource circularity, thermal system resilience, and long-term grid flexibility through next-generation material handling and processing solutions.

Ready to power your plant with smarter fuel prep?

Let’s design your next Waste Wood Shredding Line for Heat Production—tailored for performance, efficiency, and Nordic resilience.

We have received your information and will be in touch with you shortly. Thanks!