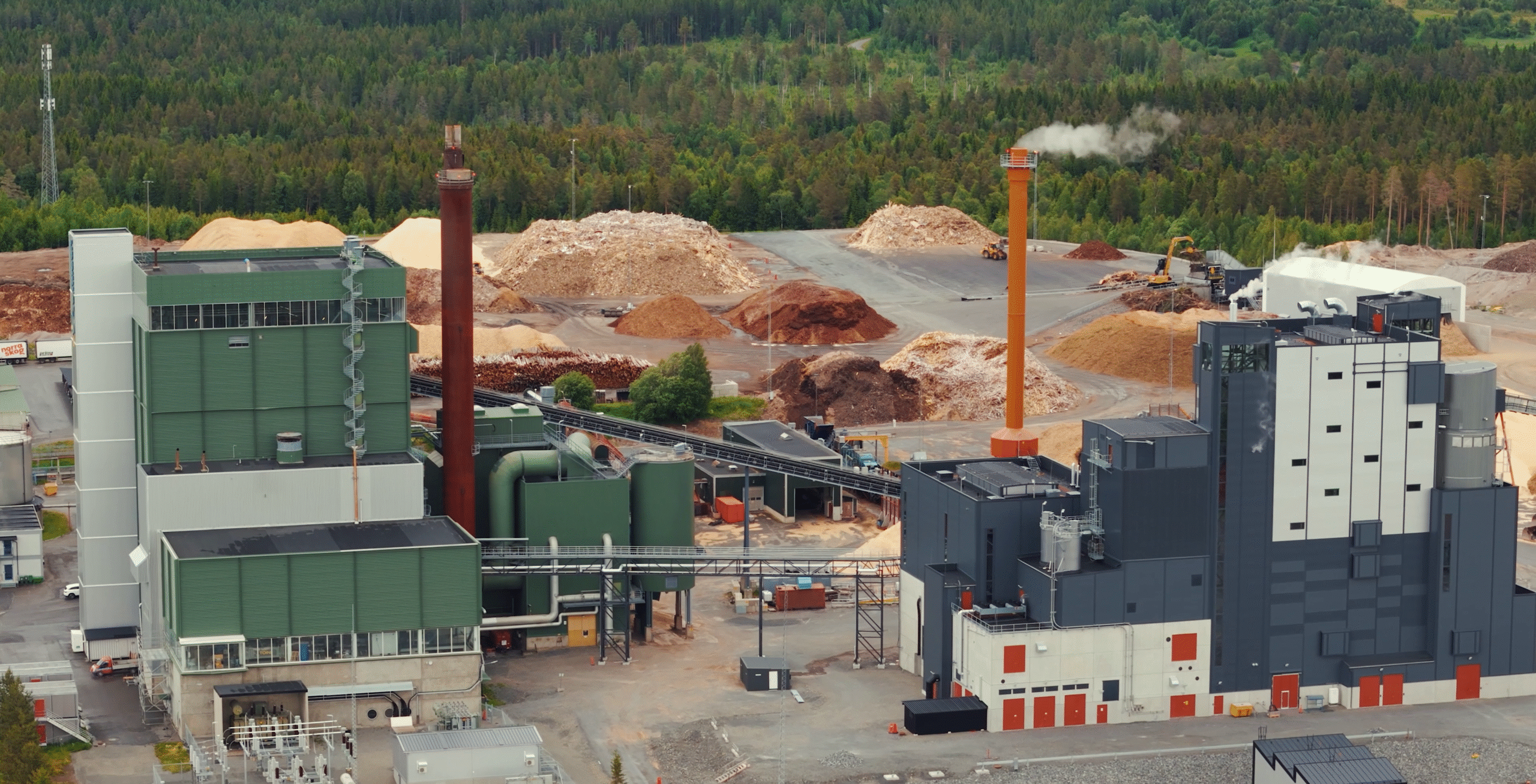

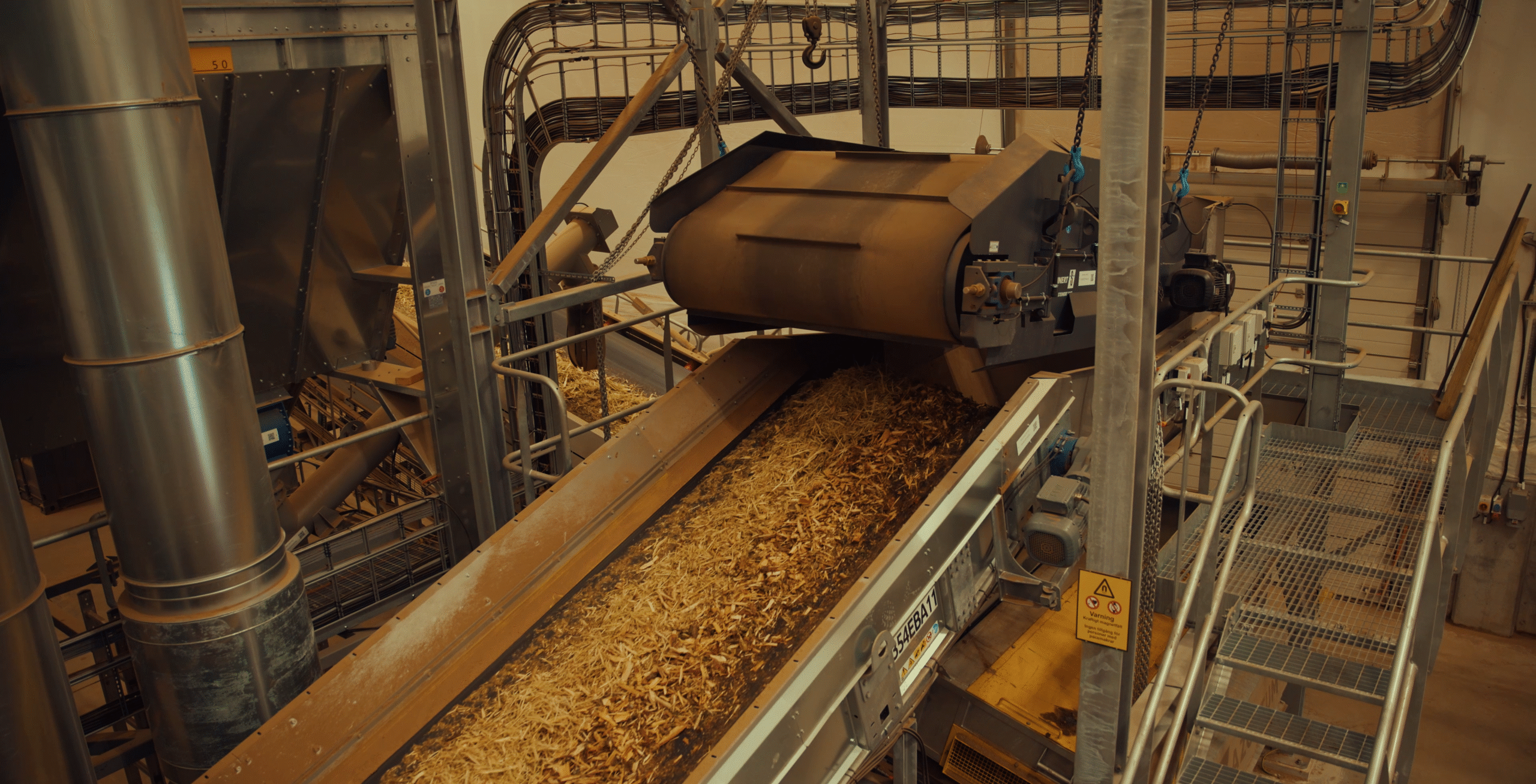

Case study: Jämtkraft’s Wood Shredding Line for CHP Plant in Östersund

RECAP

- Increased recycled wood use from 20% to 75%, reduced fuel costs, and improved boiler performance for efficient district heating to 50,000 residents.

- Two-stage shredding that handles diverse biofuels at 70 tons per hour with a consistent P63 output.

- Winter mode and dust suppression systems provide reliable operation in extreme Swedish weather.

BACKGROUND

For over 130 years, Jämtkraft has kept the city of Östersund warm and supplied with reliable district heating, even through the harshest Nordic winters. As the region continues to grow, so does the demand for efficient and sustainable heating solutions.

To meet this demand, Jämtkraft built a new combined heat and power (CHP) plant to replace worn-out boilers from the 1980s. This new facility required a high-capacity wood shredding line capable of processing a wide range of biofuels to keep 50,000 residents warm and supplied with electricity.

Their existing shredder couldn't meet the higher throughput requirements, suffered frequent downtime, and struggled to handle the diversity of fuel types needed for the new plant.

MEETING ÖSTERSUND'S GROWING ENERGY DEMANDS

Jämtkraft’s new shredder line had to meet three critical requirements.

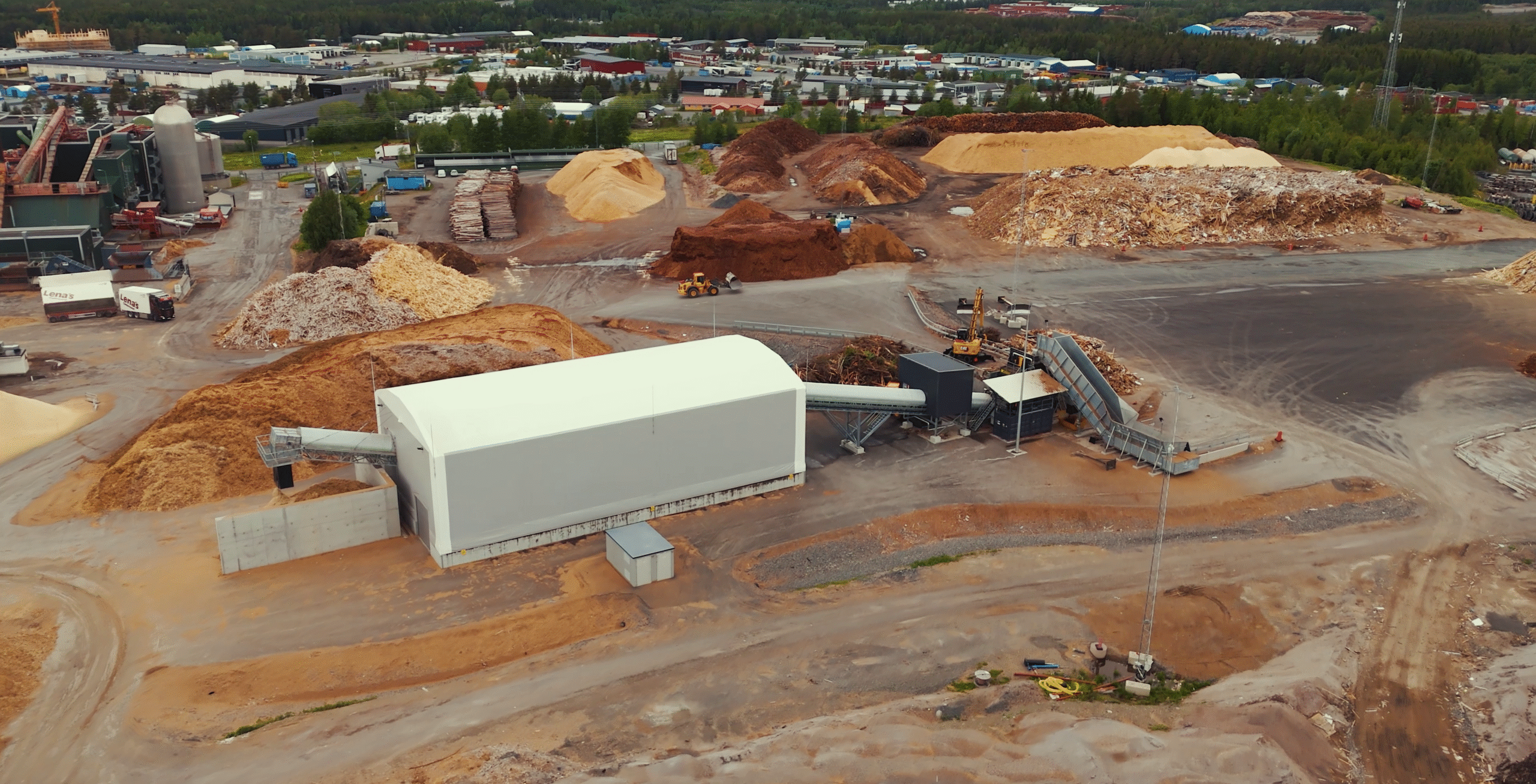

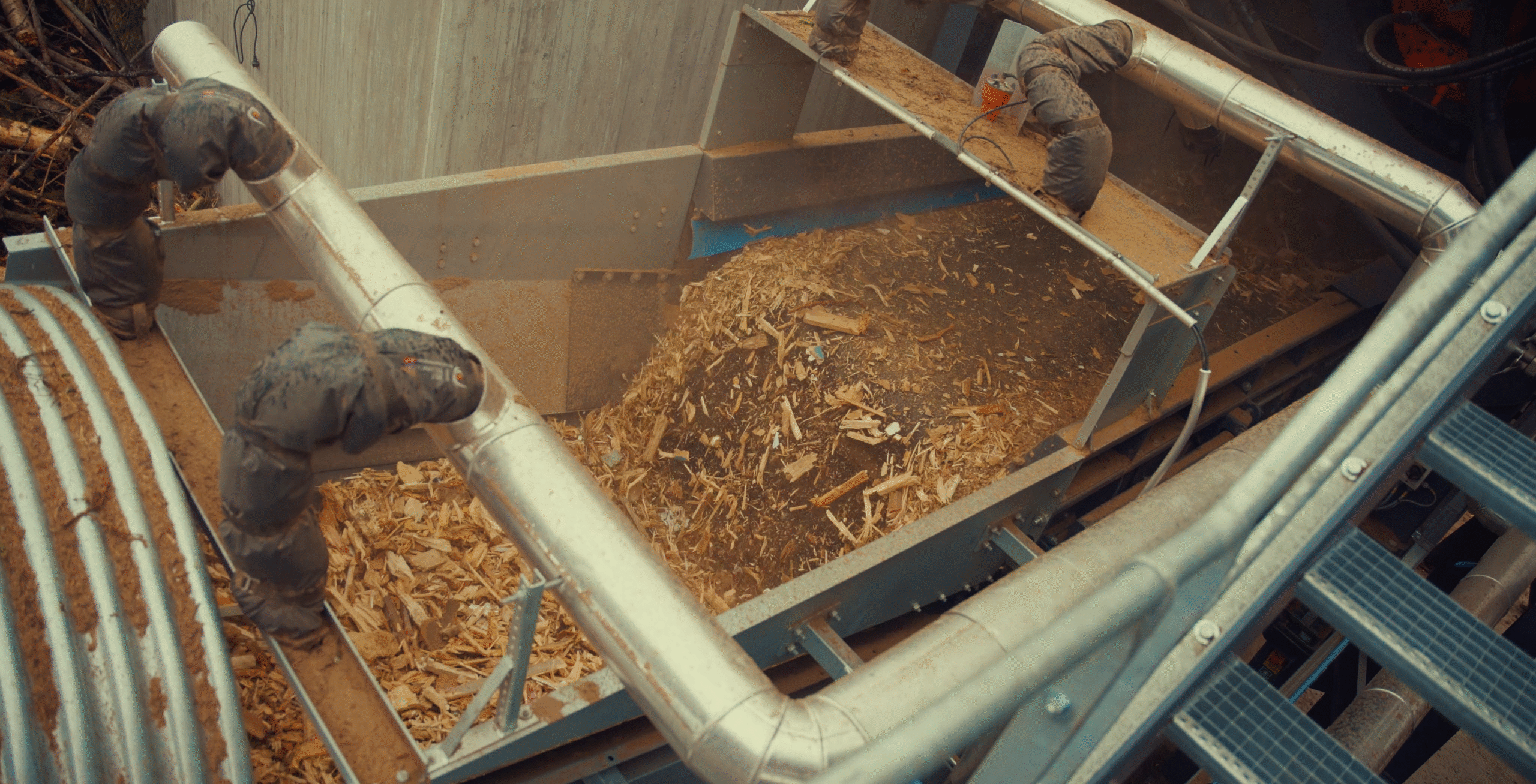

First, it needed exceptional fuel flexibility, with the ability to process almost every type of biofuel available on the market, from dry sawdust and bark to wet forest residues, such as tips and branches from thinnings or clear cuts. The line also had to handle waste wood, off-spec boards unsuitable for carpentry, and pulpwood not fit for the pulp industry, ensuring each fuel type could be processed efficiently.

Second, it had to deliver consistent output quality, producing a uniform P63 chip size and maintaining stable moisture levels, so that the boilers run smoothly and emissions are low, particularly during peak winter demand.

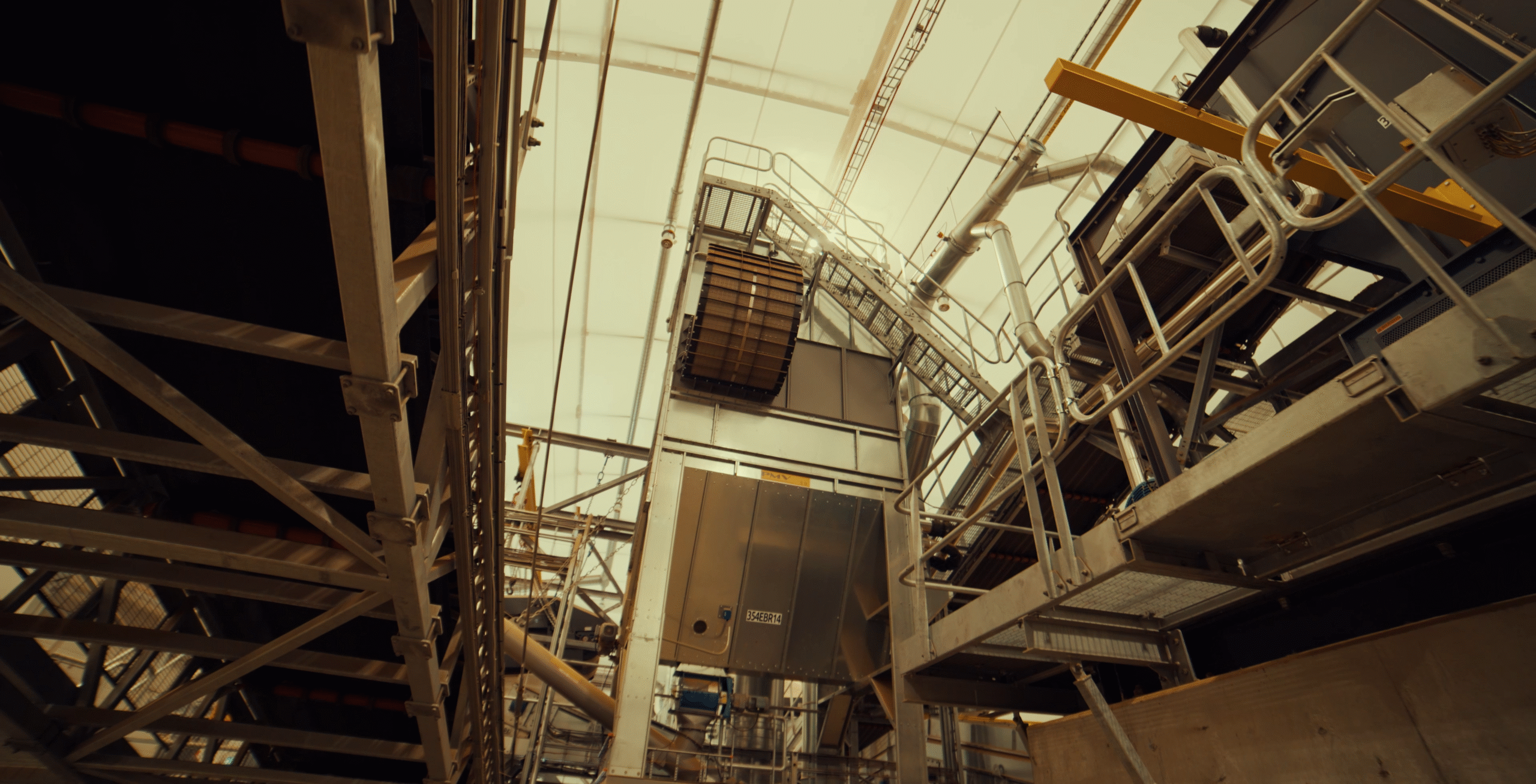

Finally, the system had to ensure high uptime and operational safety in the challenging Nordic climate, performing reliably through freezing winters and dry, dusty summers while remaining safe to operate and easy to maintain for operators.

DESIGNING FOR FLEXIBILITY, CONSISTENCY, AND UPTIME

Jämtkraft partnered with Azortum to design, deliver, and install a high-capacity wood shredding line tailored to their operational needs and local climate conditions.

The solution included:

OPERATIONAL IMPACT

- Throughput: 70 tons/hour at P63 fraction.

- Increased Fuel Range: Capable of processing materials that other operators reject, allowing sourcing of lower-cost materials without compromising output quality.

- Higher Waste Wood Utilisation: Supports Jämtkraft's target of increasing recycled wood use from 20% to 75%.

COLLABORATION BUILT ON TRUST

From the first meeting, which we held in the middle of a snow blizzard, Jämtkraft and Azortum established a relationship built on trust, open communication, and shared objectives.

- “I didn’t think I would see those guys again,” recalls Daniel Iversson, Biofuel Project Manager at Jämtkraft, “but they came out good, and it has been a joy since day one.”

In his words, Jämtkraft chose Azortum because of:

- Proven flexibility in design and delivery.

- High capacity performance tailored to their needs.

- Strong focus on operator safety and working environment.

The new shredding line ensures Jämtkraft can meet the growing heating and electricity demands of Östersund while maintaining high efficiency, operational safety, and sustainability.

Let's discuss your project!

At Azortum, we are committed to developing unique solutions that are sustainable to operate and profitable for your company.

We have received your information and will be in touch with you shortly. Thanks!