Case study: Ecoservice’s Packaging Waste Sorting Line in Lithuania

RECAP

- Completed in less than 12 months, despite complex spatial and scheduling constraints.

- The new line processes up to 12 tons of packaging waste per hour and sorts it into 10 material types.

- Raw material recovery is now boosted by up to 100%.

REBUILDING AFTER THE FIRE

Ecoservice is Lithuania's leading waste management company. It offers a wide range of services, including packaging waste sorting, mixed municipal waste processing, construction and bulky waste management, city cleaning, and street maintenance. With a strong national presence and a focus on sustainability, Ecoservice plays a crucial role in Lithuania's efforts to recover waste and promote a circular economy.

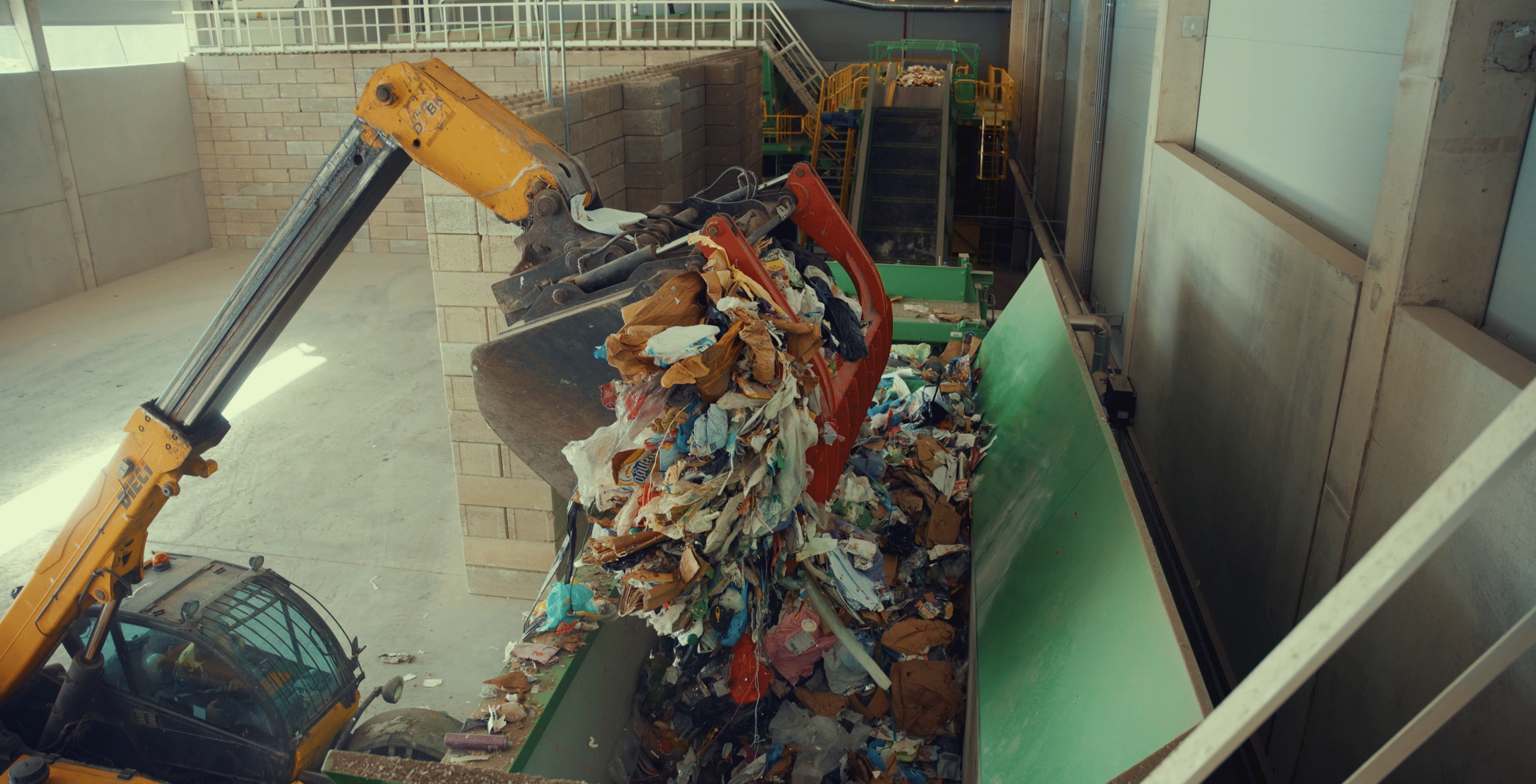

In 2023, Ecoservice's previous packaging waste sorting line was destroyed by fire. The company quickly committed to building a new, modern facility with higher capacity, greater recovery efficiency, and improved fire safety systems. The goal was to complete the new line within 18 months and integrate it into an existing building space during construction. The company invested €18 million in building a new sorting line, not just to replace the lost facility, but to elevate performance, automation, and sustainability to a new level.

TAILORED TO STRICT REQUIREMENTS

From the very beginning, Ecoservice had a clear and detailed vision for how the new packaging waste sorting line should operate. The goal was to build a line that would not only match the previous facility's capabilities but significantly improve sorting efficiency, automation, and material recovery. All of this had to be achieved within the constraints of an existing building footprint, with no expansion in width, height, or length possible.

The line had to be designed to process household packaging waste from the Vilnius region, with a throughput capacity of 12 tons per hour. It needed to sort material into at least 10 different fractions while minimizing manual labor and maximizing the purity of recovered materials.

At the same time, the new line had to be equipped with modern fire safety systems, ensure stable operation under continuous load, and deliver flexible material handling suited to the region's growing recycling needs.

The strict timeline set by Ecoservice required overlapping of the construction, engineering, and installation phases. Many components were delivered and mounted before the building was fully ready, requiring tight coordination between teams to keep the project on schedule.

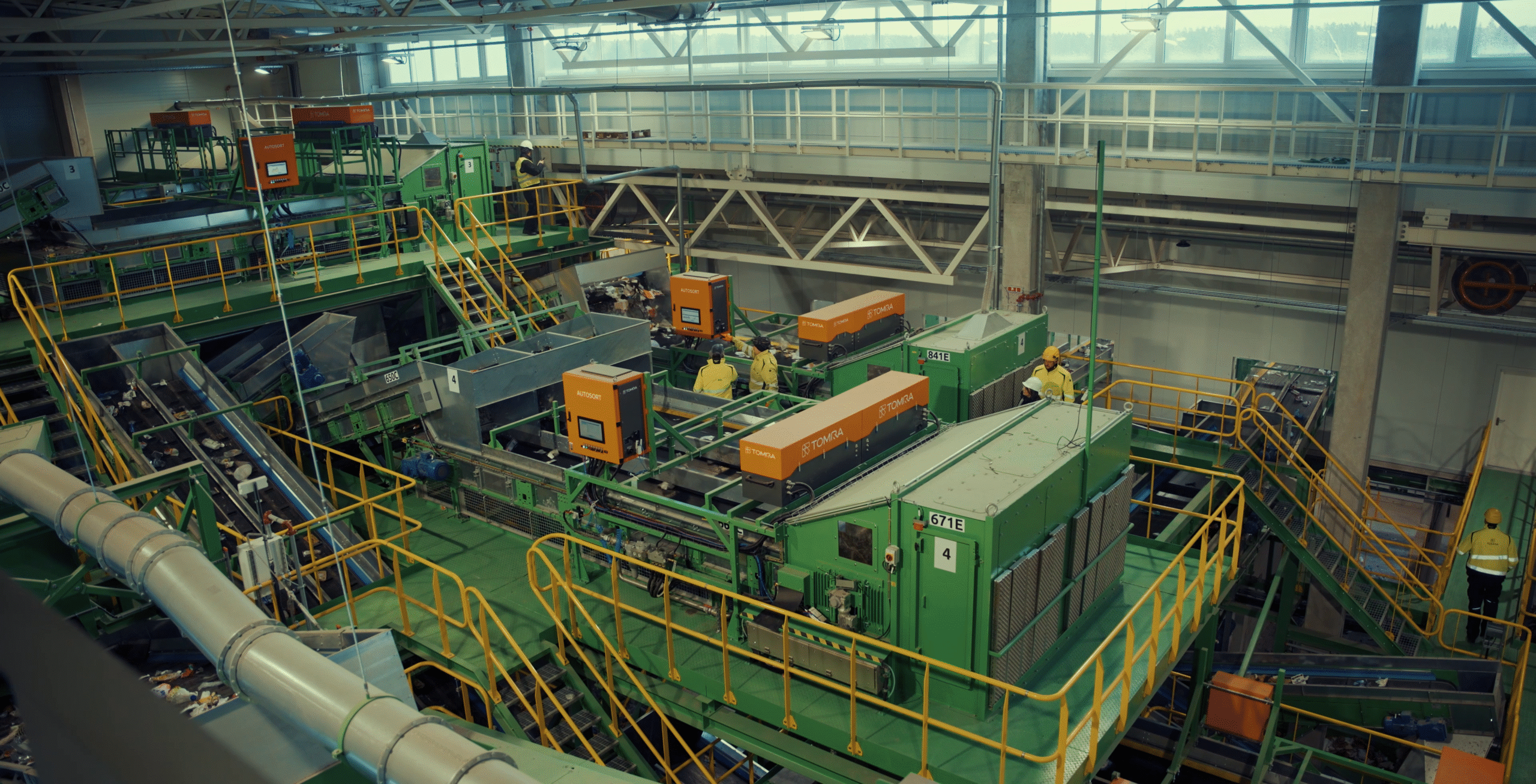

A COMPACT, HIGH-CAPACITY SORTING SOLUTION

The new line developed for Ecoservice is a fully automated packaging waste sorting system designed to process 12 tons of household packaging waste per hour from the Vilnius region. It combines a wide range of modern sorting technologies, including a drum screen, optical sorters, eddy current separators, and magnet separators, all integrated into a tightly optimized layout. The system is supported by advanced fire detection and suppression equipment to meet the highest safety expectations.

This solution fulfills all of Ecoservice's key requirements:

- Sorting waste into 10 distinct material fractions;

- Increasing operational efficiency by 3 times;

- Enabling a higher quality of recycled output with significantly reduced manual labor.

The plant also prepares Ecoservice for future growth by offering flexible material handling options and improved line reliability under continuous load.

To meet the 18-month deadline, installation began before the full engineering package was complete. Equipment such as the drum screen had to be installed through a partially finished roof, with only centimeters of clearance. Despite these conditions, the line was completed and entered the testing phase ahead of schedule.

CLOSE COLLABORATION FROM START TO FINISH

Strong and ongoing collaboration between Ecoservice and Azortum made the successful delivery of the project possible. From the early planning stages through installation and testing, both teams maintained close communication. Ecoservice's vision for the plant's functionality, layout, and performance remained closely involved throughout the process.

Azortum responded with a flexible, solutions-driven approach. Throughout the 12 months of working together, we proposed tailored technical solutions and made quick adjustments as requirements evolved during the implementation process.

Andrzej Juhevic, Technical Manager at Ecoservice, says that:

- "Azortum listened to what we needed and came up with one of the best possible solutions. They provided great quality for the money."

This strong working relationship helped overcome time pressure, technical constraints, and the challenges of an active construction site. This ensured that all milestones were met and the project progressed without delay.

The new Ecoservice line in Vilnius is now one of the most advanced waste sorting facilities in the Baltic countries.

Write us about your project!

At Azortum, we are committed to developing unique solutions that are sustainable to operate and profitable for your company.

We have received your information and will be in touch with you shortly. Thanks!